E-MOBILITY / DESIGNWERK

RESOURCE-SAVING. MAXIMUM FLEXIBILITY. FULLY EFFICIENT.

In close partnership with the Swiss company Designwerk, ZÖLLER-KIPPER offers a range of all-electric refuse collection vehicles as a complete solution. The 3- or 4-axle electric chassis, based on Mercedes-Benz Econic and Volvo models, are available with battery capacities from 170 to 680 kilowatt hours. Which drive solution is the most suitable is determined by means of logistical analyses in the respective collection areas. The mileage in stop-go collection mode of up to 200 kilometres fully meets the user’s requirements in daily operation. All body and lifter combinations as well as crane vehicles for the underground containers can be offered on the all-electric chassis.

DO YOU HAVE ANY QUESTIONS?

HOW TO REACH US

Mr Lippardt is your competent contact for Designwerk.

You can reach Mr Lippardt at:

Mobile: +49 4531 88019-25

Mail: t.lippardt@zoeller-kipper.de

WASTE BIN WASHER

THE MOBILE LAUNDERETTE

The ZOELLER bin washer not only gets the bins wet, it gets them clean!

Waste bins shine like new again after being cleaned by the waste bin washer. With a water supply that lasts all day, the vehicle is the most efficient waste bin washer – whether on a fixed place or on the collection route. It delivers what it promises!

Details

- Efficient cleaning of containers up to MGB EN 840-1, 2, 3

- Can be used in stationary cleaning

- Water supply for the entire daily requirement

- All water-bearing components, tank and water chamber (inside) are made of stainless steel

- Cold and hot water

- Two- and three-axle chassis

- Spray-gun for manual post-cleaning

- Suitable for manual, automatic and special container lifter versions

DOWNLOADS

Brochure Waste Bin Washer

272,07 KBQUICK FACTS

- Complete bio-tightness due to all-round seal

- More usable volume thanks to optimised body design with integrated intermediate frame

- Hydraulic concept designed for energy efficiency and modular control system, already future-orientated for alternative drives

- Hydraulic and mechanical tailgate locking device with force-locking claw lock

- No profile tapering the body due to contour-integrated, roof-mounted rear lifting cylinders

- Variable body concept in length, width and height

- Robust, maintenance-free linear guidance of the carriage plate via centrally lubricated sliding elements

Medium X4

The Manoeuvrable

No more long manoeuvring: The rear loader with a usable volume of 18 to 25 m3 as standard is particularly suitable for collection in collection areas with narrow access roads thanks to its compact tailgate and low overhang – ideal for waste and recyclables collection in inner-city areas. For special applications, the body volume can be increased to up to 27.5 m3 and, in the MEDIUM X4H version with a 200 millimetre higher collection box, to up to 30 m3. Roof-mounted tailgate opening gliders ensure an optimised shift in the centre of gravity towards the front axle – while also protecting against damage during unloading. Plus: A weight-optimised, reinforced body increases the payload.

DETAILS

- Manoeuvrability & optimum axle load distribution due to short rear overhang

- High loading & compaction performance due to short packer plate, steeply positioned carrier plate and fast cycle time

- X4N: Body width 2300mm

- X4H: Increased body volume, 200 mm higher

- Closed tailgate suitable for DIN interface or integrated lifter systems

- Clean Option

- High level & low level lifter

- Residual waste

- Paper, cardboard, carton

Medium X2

THE ALLROUNDER

The all-rounder with optimised body volume and large hopper offers a usable volume of 21 to 24 m3 as standard, up to 30m3 for special applications – and in the MEDIUM X2H version with a 200 millimetre higher body and the same vehicle length, even a volume of up to 31 m3. This is perfect for collection in areas with wide access roads and a high proportion of 4-wheel containers. The refuse fraction can be set on the control terminal: Recyclables, residual waste, biowaste and paper are compacted at the optimum pressure – glass is also available on customer request. Also ideal for the collection of recyclables in bags.

DETAILS

- Large hopper volume

- The right body for all applications

- X2H: Body raised by 200 mm

- X2L: Body reduced by 200 mm

- Closed or open tailgate

- Clean Option

- for high-level lifter, low-level lifter and commercial lifter

- for open loading

- Residual waste

- Paper, paperboard, carton

- Industrial / Commercial Waste

Downloads

Brochure Medium X2

243,88 KBQUICK FACTS

- Closed refuse collection, low dust and odour emissions

- Kinematics, separate lifting and swivelling movement

- Lowering movement due to gravity

- Fully hydraulic drive

- Swivelling movement via proven rotary drive

- Available as an automatic or manual lifter

DELTA PREMIUM 2322

OUR BESTSELLER

In conjunction with a MEDIUM X2 or MEDIUM X4 rear-end loader, the new automatic lifter with two independently operating lifting and tipping units with lifting comb and a flexible installation range of 1150 – 1550 millimetres offers an optimum standing position with the best possible positioning and shoulder clearance as well as preparation for additional cameras for footboard monitoring. Also included: A new barrier design – optionally extendable for fully automatic emptying of 4-wheel bins. Perfectly suited for residential areas – can also be optimally operated by one person. The special feature of the DELTA 2322: The Diamond front pick-up.

Details

- Pronounced power dissipation

- Gentle on containers thanks to double pallet truck support

- High ground clearance thanks to automatic lifting of the lifting carriage when moving on

- Optimised emptying behaviour thanks to active container retention

- Passive bin locking

- DIN version

- Automatic and manual actuation

- High ground clearance thanks to automatic lifting of the lifting carriage when moving on

- DIN hinged arm design

- Single lifter mounted on panel DIN version

- Special container for e.g. Diamond container and Ochsner

- Preparation for weighing and RFID systems

- Weight optimisation through various lifting carriage devices

- Quick-change device for swivel hinged door and lifter

- Deep Scan

- Safety equipment

- Worker Protection

- Compatible with vehicle widths 2300 mm and 2500 mm

DELTA PREMIUM 2316

FOR FORWARD THINKERS.

The split automatic lifter with two independently operating lifting/tipping units with lifting comb offers a weight advantage in combination with the vehicle, as the swivel hinged door weighing around 200 kilograms is no longer required. In addition, it extends across the entire width of the rear of the vehicle and can therefore move closer – this reduces the overhang and achieves a better axles distribution. Areas of application: Ideal, for example, in conjunction with the MEDIUM X4 for narrow lanes in city centres.

Details

- Shortening of the rear overhang by removing the swing door

- Weight optimisation in the overall system

- Larger overall width

- Lateral working area protection device (safety barriers) available as internal and external variants

- DIN hinged arm design

- Preparation for weighing and RFID systems

- Weight optimisation through plastic covers

- Automatic detection and changeover to four-wheel container

- Worker Protection

- Deep Scan

- Compatible with vehicle widths 2300 mm and 2500 mm

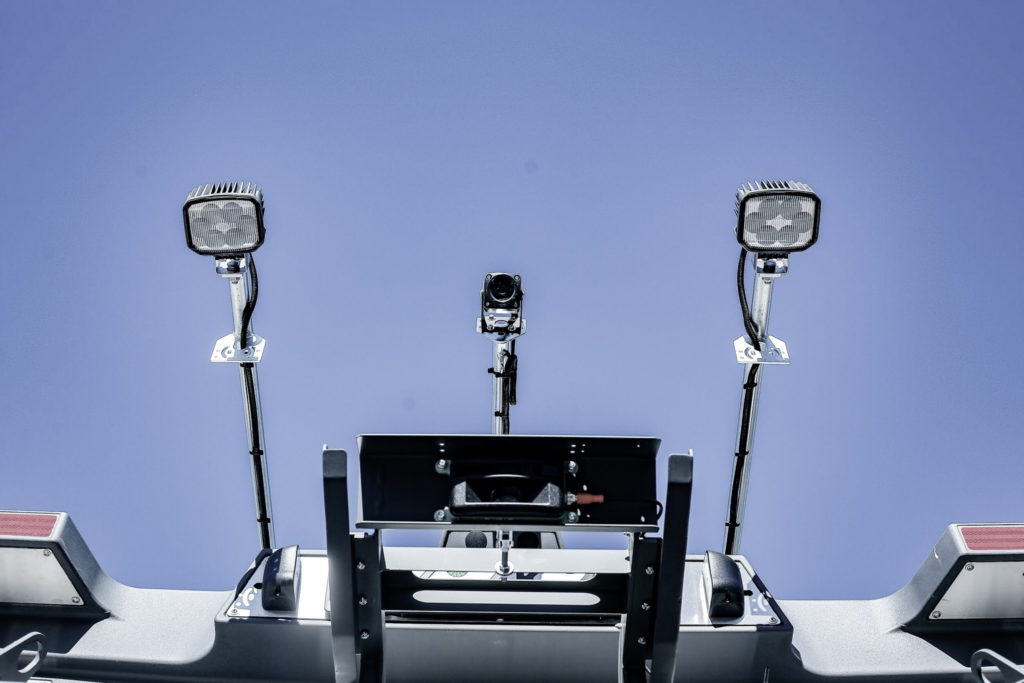

WASTE SCANNING

PRODUCTS

With products “DeepScan” and “SmartScan” we enable waste analysis directly in the collection vehicle at the collection point. With analysis of the qualitative collection in real time, as well as a modern online portal “ScanSuit” we offer many options for our customers to sustainably improve the separation quality.

Quick Facts

DeepScan utilizes physical characteristics of electromagnetic detection, which responds to metals within the entire bin. It allows for customized settings and correlation analysis between scanned metals and other contaminants. Based on this analysis, actions such as stopping the lifter and preventing emptying can be taken. Integration is possible with most lifters from Kirchhoff Group members and third-party manufacturers. DeepScan can be installed ex works as well as retrofitted.

Deepscan

Characteristics

Particularly designed for biodegradable waste.

Limits of contaminants through biodegradable waste law are digitally observed, transferred and stored through scanning at the collection point.

The entire bin is scanned from top to bottom to detect contaminants.

Acoustic and visual signals give direct feedback on the grade of waste contamination.

System settings (sensitivity, Lifter-Stop, etc.) can be customized by clients through their web portal account.

General Data (GPS, RFID, etc.) is combined with sensor analytics and transferred to the web-portal.

The System can be installed on single and double bin lifters as well as sideloaders and scan two- and four-wheel plastic bins.

Quick Facts

DeepScan utilizes physical characteristics of electromagnetic detection, which responds to metals within the entire bin. It allows for customized settings and correlation analysis between scanned metals and other contaminants. Based on this analysis, actions such as stopping the lifter and preventing emptying can be taken. Integration is possible with most lifters from Kirchhoff Group members and third-party manufacturers. DeepScan can be installed ex works as well as retrofitted.

Deepscan

Characteristics

Particularly designed for biodegradable waste.

Limits of contaminants through biodegradable waste law are digitally observed, transferred and stored through scanning at the collection point.

The entire bin is scanned from top to bottom to detect contaminants.

Acoustic and visual signals give direct feedback on the grade of waste contamination.

System settings (sensitivity, Lifter-Stop, etc.) can be customized by clients through their web portal account.

General Data (GPS, RFID, etc.) is combined with sensor analytics and transferred to the web-portal.

The System can be installed on single and double bin lifters as well as sideloaders and scan two- and four-wheel plastic bins.

Quick Facts

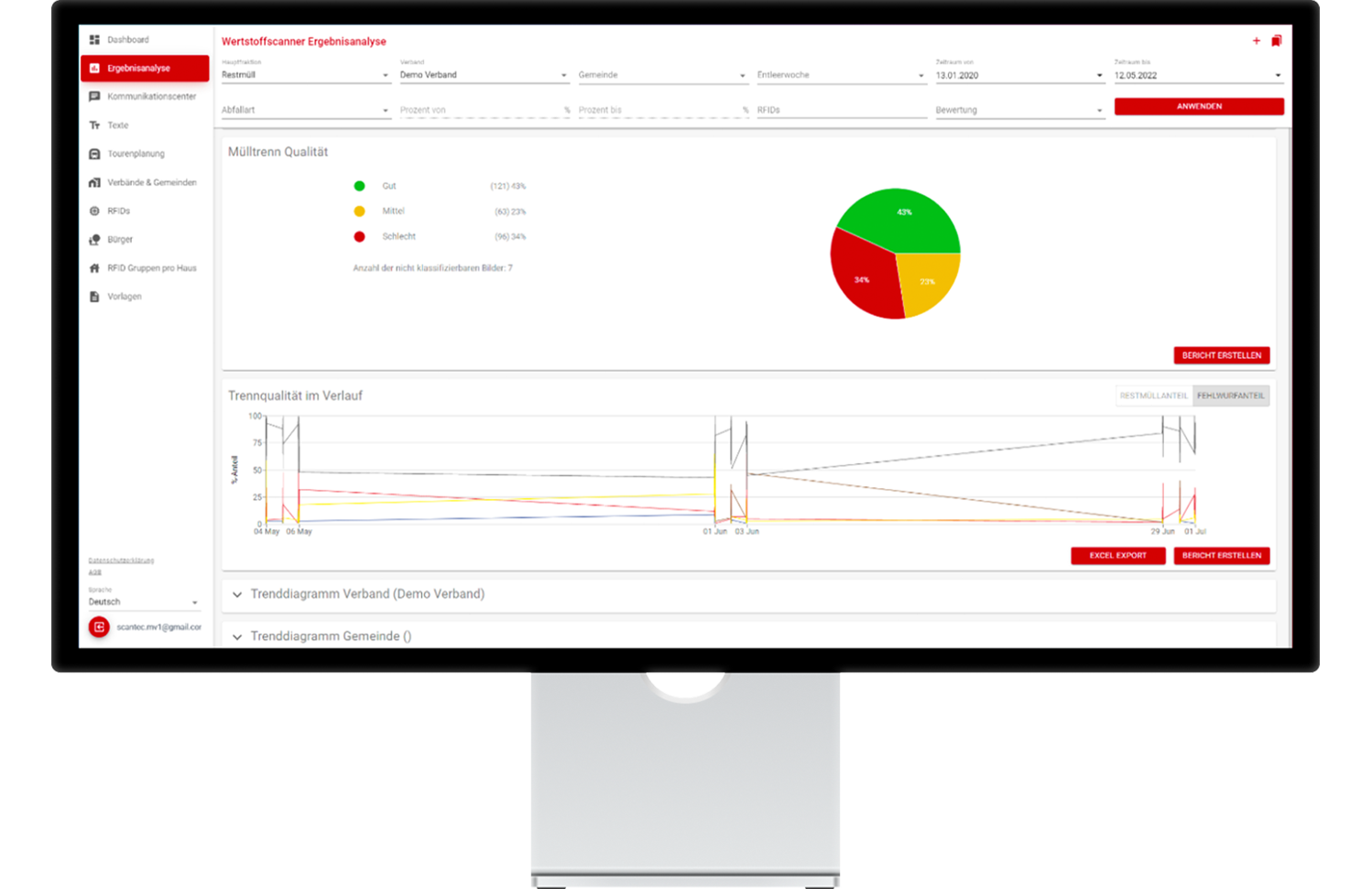

Data collected by SmartScan and DeepScan is transferred, analyzed and reported within our web-portal ScanSuite. Through the use of big data – in this case waste quality and quantity in combination with vehicle, superstructure and geographical data, various reporting can be provided and customized.

Especially combination of data from DeepScan and SmartScan raises the quality level of waste composition from various waste streams. It allows filtering of high amount of contaminants at the source and providing crucial data for further processing. Following default reports can be provided, but further customization is possible.

ScanSuite

Characteristics

HEAT MAPS

Heat-Maps and quality information

REPORTING

Detailed-Reporting – Filter by areas, routes, streets, data, etc.

FEEDBACK

Bin specific analysis and feedback with recommendations for action to the public/client

NEAR REAL TIME

Direct and timely, targeted information with reference to current analysis

QUICK FACTS

- Liquid-tight base assembly, raised in the front area

- Particularly suitable for industrial, commercial and bulky waste collection

- Variable body concept in length, width and height

- Robust, low-maintenance compaction unit

MAGNUM X1

The Muscle Man

Boards, doors, cabinet walls – it swallows everything, tirelessly. In the endurance test, the X1 impresses with its durability and robust design. The optimised position of the inner rave ensures the least possible splintering when loading, crushing and compacting bulky waste. And compared to its big brother, the Magnum XXL, the X1 is also a little lighter. The muscle man is suitable for all commercial lifters in the ZOELLER product range. In addition, the X1 is of course a member of the MAGNUM Family through and through, with all the advantages of a variable bodywork concept through to the future-orientated focus on alternative drives.

Details

- Closed construction of the carriage and packer plate, therefore no waste deposits

- Maximisation of the loading density through convenient fraction preselection on the operating terminal

- More usable volume thanks to optimised body design with integrated intermediate frame

- Hydraulic concept designed for energy efficiency and modular control system, already future-orientated for alternative drives

- Hydraulic tailgate locking device with force-locking claw lock

- No profile tapering the body due to contour-integrated, roof-mounted rear lifting cylinders

- Robust, maintenance-free linear guidance of the carriage plate via centrally lubricated sliding elements

- X1H: body raised by 200 mm

- Open tailgate bulky waste

- Open tailgate commercial lifter

- Bulky waste

- Industrial & commercial waste

Downloads

Brochure MAGNUM X1

493,82 KBMAGNUM GPM

The uncompromising one

All types of waste – one vehicle: Whether bulky, wet or even hazardous, thanks to the robust compaction mechanism and maximum interior capacity, the Magnum GPM can handle large quantities of waste in just one pass; and the curved floor and fully welded body significantly reduce the risk of leaks and corrosion. The sides of the bodywork are made from a single piece of high-strength steel, yet the Magnum GPM is a real light- weight. This maximises the payload and saves energy. It is available in standard width and narrow gauge, ideal for constricted urban areas. It can also be supplied with hybrid technology on request.

Details

- Tailgate with robust compaction mechanism consisting of guide frame and compaction plate

- High clearing capacity with complete clearing of the hopper through with every compaction cycle

- Smooth-walled highly processed steel construction

- Hydraulic, electrical and pneumatic components arranged in a protected position

- Premium cylinder, hollow-bored piston rod, no hydraulic hoses in the compaction area

- Compaction unit in robust steel construction, cylinder-guided

- Open tailgate commercial lifter

- GAMMA 2349 GCB (bar lift, continuous manual or split lift, split automatic)

- MEGA 456 GEC (bar lift, continuous manual or split lift, split automatic)

- MEGA 179/479 GHC (bar lift, continuous manual or split lift, split automatic)

- Industrial & commercial waste

- Container removal MGB EN 840-1, 2, 3

Lifter & Container Solutions

Container |

Lifter |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

GCB

|

Split

|

GEC

|

GHC

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EN-840-1-

120L-400L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EN-840-2-

500L-1200L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EN-840-3-

770L-1300L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EN-840-4-

750L-1600L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EN-12574-1-

2500L-4500L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

EN-12574-1-

2500L-5000L |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| = Standard = Optional |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Downloads

Brochure MAGNUM GPM

487,96 KBMAGNUM XXL

The Indestructible One

Much more than just a big mouth – the hopper has a clearing volume of 2.3 m³, the collection container offers a load capacity of 18 to 31 m³. If you want a little more: The H-variant (MAGNUM XXLH II) offers 200 mm more height with the same body length and thus approx. 10 per cent additional volume.

Rigid, smooth-surfaced collection containers, the use of highly wear-resistant fine-grained steel (10 mm loading trough, 6 mm side walls) and optional additional reinforcement with side and roof frames make this refuse collection vehicle extra robust.

Ideal for bulky waste operations with open loading or – with appropriate tailgate preparation – for the collection of large containers and commercial waste.

DETAILS

- Closed construction of the carriage and packer plate, therefore no waste deposits

- Maximisation of the loading density through convenient fraction preselection on the operating terminal

- Central electrics behind side inspection door

- X1H: Body raised by 200 mm

- Open tailgate bulky waste

- Open tailgate Commercial Lifter

- Commercial Lifter

- Bulky Waste

- Industrial & Commercial Waste

Downloads

Brochure Magnum XXL

289,46 KBQUICK FACTS

- Integrated tailgate

- Variable rave rail for convenient handloading of bags and loose loads

- Fully automatic operation of the compaction unit when the guide flap is raised

OMEGA 359

FOR TOURS THAT REQUIRE CUSTOMISED WORK

Die durchgängige manuelle Kammaufnahme kann 2-Rad- und 4-Rad-Gefäße erfassen, der Kippmechanismus wird per Joystick oder Drucktaste ausgelöst. Lässt sich effektiv im 1-Mann-Betrieb bedienen – und eignet sich ideal für selektive Spezialabfuhren, z. B. von vergessenen Mülltonnen, in Straßen mit Rückfahrrestriktion oder auf Marktplätzen. Plus: Eine abklappbare Rutsche ermöglicht zusätzlich den bequemen Handeinwurf. Optimal in Kombination z. B. mit dem MICRO XL-Hecklader.

Details

- Manual lifting comb

- Integrated inner rave, suitable for use with bulky waste

- Fold-out operating unit for container pick-up in one-man operation

- Folding container support for more ground clearance

- Pick-up function

- Preparation for weighing and RFID systems

- Lock and shake device for skip containers

- Hydraulically folding guide flap

- Compatible with vehicle widths 2100, 2300 and 2500 mm

E-MOBILITY / OEM

CLIMATE-NEUTRAL WASTE DISPOSAL WITHOUT COMPROMISES.

Our versatile bodies and electric and hydraulic lifters fulfil all waste management requirements. And they fit all OEM electric chassis, regardless of the drive technology. In terms of climate-neutral and resource-conserving waste disposal, this makes it possible to handle daily tours with e-mobility as required. The mileage in stop-go collection mode for electrically powered OEM chassis is 150 to 160 kilometres. The same compression, power and speed as with conventional, comparable diesel drives.

DO YOU HAVE ANY QUESTIONS?

HOW TO REACH US

Mr Lippardt is your competent contact for OEM.

You can reach Mr Lippardt at:

Mobile: +49 4531 88019-25

Mail: t.lippardt@zoeller-kipper.de

QUICK FACTS

- Fast refuelling instead of a long charging cycle

- Large operation distance

- High efficiency

BLUEPOWER

WITH HYDROGEN FOR A CLEAN TOMORROW

An emission-free, virtually silent hydrogen drive that, in combination with a fully electric chassis, achieves the operating times and ranges of conventionally powered vehicles. Utilises a glider based on the Mercedes Benz Econic chassis – in combination with a drive train developed in-house. Ideal for use in the waste disposal industry and for cities, local authorities and waste disposal companies that want to rely on pioneering technology.

Details

- H2 fuel cells as range extenders

- Modular tank & fuel cell system

- Utilisation of recuperation energy

- Minimal noise emissions

- Use of a basic chassis from series production

- Tour data analysis for calculating energy requirementss

- Use in combination with the X-Family

- Use in combination with all common electric and hydraulic lifter systems

- Option to add various assistance systems

- On-Board Charger (OBC)

DOWNLOADS

Brochure Bluepower

526,09 KBDO YOU HAVE ANY QUESTIONS?

HOW TO REACH US

Mr Lippardt is your competent contact for the Bluepower.

You can reach Mr Lippardt at:

Mobile: +49 4531 88019-25

Mail: t.lippardt@zoeller-kipper.de